Corrosion is a naturally occurring electro-chemical process that deteriorates metal or its properties because of a reaction with the environment. Utilities have been under pressure for years to better inspect and replace aging gas pipe lines. According to the Federal Pipeline Agency, the U.S. has more than 2 million miles of pipelines. That’s enough to circle the earth about 100 times, with 90,000 of those miles located right here in Seward County. Many of these pipelines were laid years before sprawling communities were erected around them. An interview with Dr. Duane Dunn, president of Seward County Community College/ Area Technical School, revealed that during the school’s research in proposing a plan to implement a program to service those needs “looming and expected massive retirements” was one reason for the decision to start a program of this type. “The baby-boomers are retiring. Most of the corrosion engineers are facing retirement in the next two to seven years. The folks we work with in the industry are saying that they have no one trained to move into those fields. “They have been pulling people from other jobs and placing them in as corrosion techs. As a result, with an aging infrastructure as well, the need for trained technicians has become more and more prevalent,” Dunn said. “We really tried to find a program that was not replicated at any other colleges in Kansas.” SCCC/ATS is one of only two schools in the nation to offer corrosion technology for certification. According to Dunn, students who are certified can step into jobs within the industry with as much as $50,000 a year to start.’ “It’s a great local industry need, and as an institution, we expect this program to be one of the key programs for the college for the next several years and on into the future. “We really wanted our establishment to be known as the place to go.” The associate degree program is in its second year with an expected 10 students graduating this May. Blake Kuharic, sophomore SCCC/ATS, said, “Basically, right now we are studying internal corrosion; we are studying different things that happen inside the pipeline, different bacteria, and different build-up of metals.” Kuharic is in one of the first class to graduate the program, “It’s an extremely fast growing industry, when my instructor was starting out there were no programs, it was basically a ‘learn from experience’ situation. Now there are classes that you can take for each specific type of corrosion,” Kuharic said. Derek Fuller, sophomore SCCC/ATS, will also graduate this may. “I have learned quite a bit. I got lucky coming into the program having taken chemistry all ready. The program has been great so far, especially since I got to do an internship with DCP this summer.” What I learned there reinforced everything that I learned in class, as far as, what to look for, how to analyze things, how to use the equipment,” Fuller said. “I came out of a background of bartending and selling Kirby vacuum cleaners, so I know anyone could do it. It’s outside; it’s something different all the time, so if you are looking for those types of things and you like a challenge, then I would say it is for you.”

Corrosion Explosion: Jobs for corrosion technicians in high demand

October 11, 2012

Tags:

More to Discover

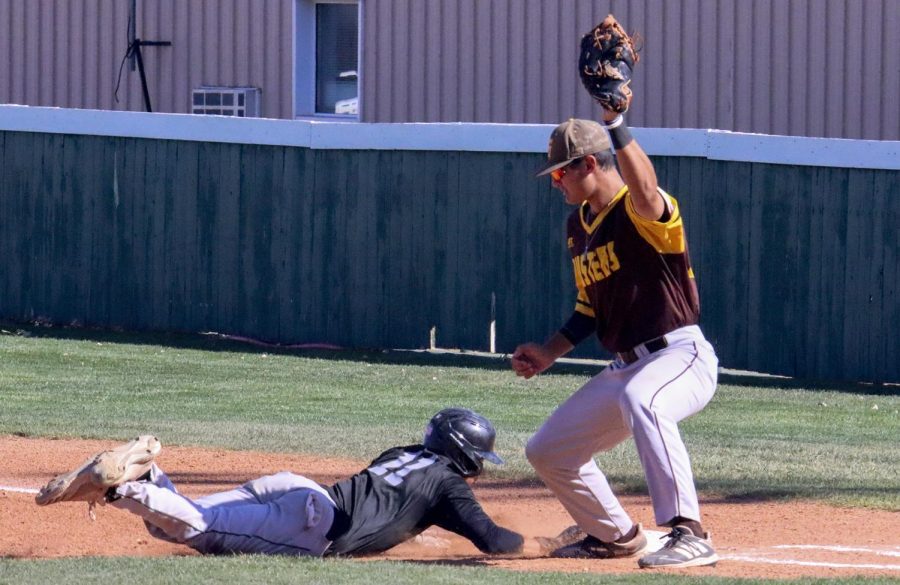

![The sophomores were recognized on the field instead of walking across the stage during their doubleheader. They received their diplomas and a picture of themselves playing during their career at Seward. [Pictured left to right are Dylan Day, Reed Thomas, Jase Schneider, Mason Martinez, Gannon Hardin, Brody Boisvert, and Zach Walker]](https://crusadernews.com/wp-content/uploads/2022/05/WEBDSC_0275-900x454.jpg)