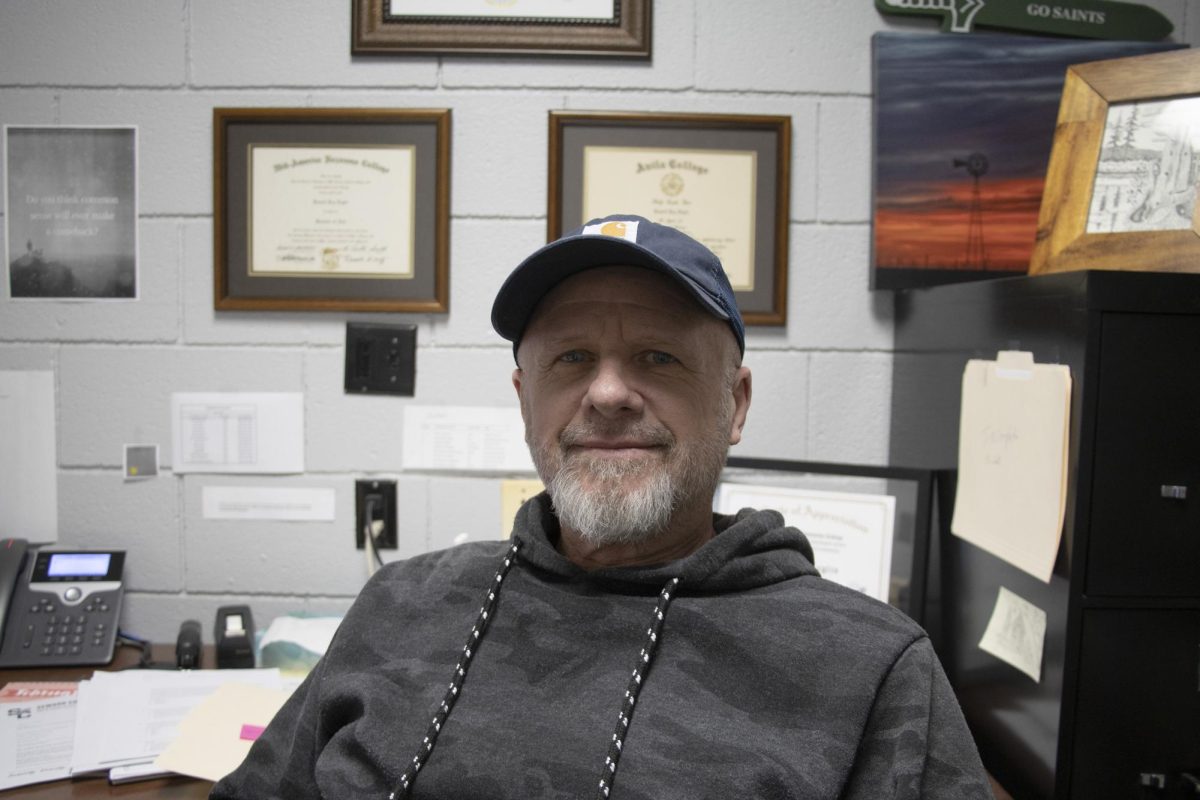

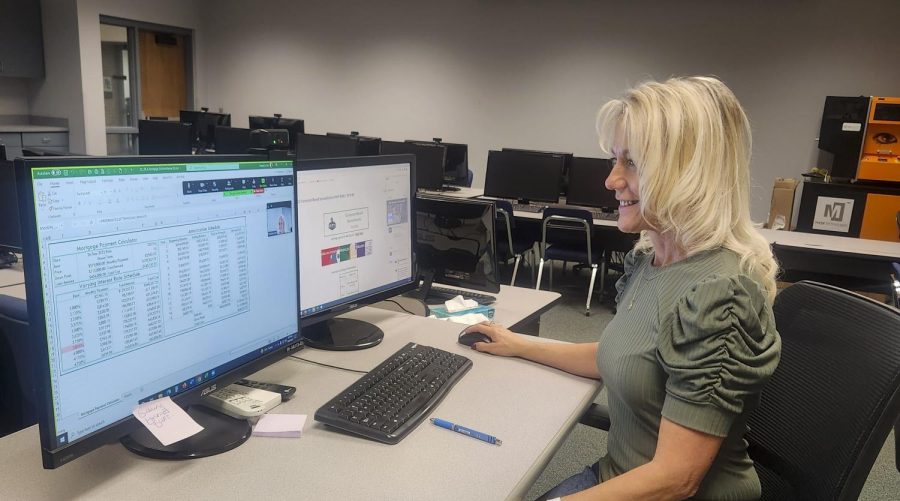

Manufacturing Day was a chance for the drafting and design department to show off their new addition to the program. Their new 3-D printer has been attracting a lot of curious wanderers and Steve Merz, drafting and design technology instructor, as well as his students, were more than happy to walk anyone through the process of their new “toy.” The first step to creating a printable item is designing and creating a three-dimensional file in a software called Catalyst. Students can design anything from a nut to individual pieces that can be put together to build a contraption. Once the file is complete, it is sent to the operating program for the machine and the operating system takes care of the fancy conversions and everything else that happens internally. The operating program then prepares a “print pack”, which, according to Merz, is the programming that controls the machine. The machine then uses a spool of ABS plastic that is fed into the printer and is then melted down to two sizes of either 0.010 or 0.013. The temperature required to melt down the ABS plastic is approximately 520 degrees fahrenheit and the environment inside the printer stays somewhere around 180 degrees fahrenheit. “And that’s so the plastic doesn’t cool down rapidly,” Merz shared, “you don’t want it to so that it bonds to itself.” Merz also described the process of the printer as slow, but clarified that a 3-D printer provides a much faster process needed for prototyping. The time allotted for the printer to make an item depends on the size of the item it is making. The printer makes layers of 1/10,000th of an inch at a time. The ABS plastic that is being used for the printer is a beige color, but Merz is already thinking about shaking things up for his students and buying plastic in reds and blues and greens. As far as funding for the 3-D printer, Merz requested capital outlay funds to the board of trustees, which was later approved. The cost for 3-D printer was $30,000, and has proven to be worth every penny. Not only is the printer simple to operate, but it is also smart and safe due to the lack of access it provides when it is printing.

3-D printer enhances learning environment for students

October 8, 2014

More to Discover

![The sophomores were recognized on the field instead of walking across the stage during their doubleheader. They received their diplomas and a picture of themselves playing during their career at Seward. [Pictured left to right are Dylan Day, Reed Thomas, Jase Schneider, Mason Martinez, Gannon Hardin, Brody Boisvert, and Zach Walker]](https://crusadernews.com/wp-content/uploads/2022/05/WEBDSC_0275-900x454.jpg)